FOOD FROZEN EQUIPMENT FOR BUSINESSES

Food freezing equipment is one of the solutions to preserve frozen goods used by many businesses today. Instead of using unhealthy preservatives, businesses can choose food freezing equipment for long-term use, reduce costs and bring to the market safer products for consumers.

What is the definition of proper food freezing?

Cooling and freezing are two mandatory product preservation processes when distributing and trading frozen foods. According to the sequence, the product must be cooled and frozen before storing in cold storage for preservation.

Meat is refrigerated before being put into cold storage

However, in practice, some people ignore this process and think that storing goods in cold storage is equivalent to cooling and freezing products. Due to the lack of knowledge and experience in this work, businesses often put goods that have not undergone the correct freezing process into cold storage for preservation. As a result, several goods of the enterprise do not meet the standard quality after being released from the storage.

However, the cause is always thought to be that the food preservation process in cold storage is not good enough. But in fact, the problem is in the stage of cooling - freezing before storing.

Many people still believe that the cause of meat quality loss is cold storage

Are businesses freezing their products properly? It's time to find out more useful information related to this issue, especially how to freeze products properly.

As a leading prestigious cold storage in the Northern region and with extensive product freezing experience, Ha Noi cold storage would like to share some of our experiences for store owners/businesses to refer to when trading frozen food in the market!

Questions about freezing products

What is food freezing? Is this any different from putting fresh food in the fridge or something like that? Is a refrigerator considered a food freezing device? The above questions will be answered by Nam Ha Noi cold storage as follows.

What is food freezing? This is a common method to refrigerate fresh foods such as vegetables, meat, seafood, etc. before putting them in cold storage for preservation. This method requires the use of specialized food freezing equipment (which can adjust temperature, humidity, refrigerating capacity, etc.) helps to lower the product temperature quickly while ensuring its intact quality.

There is a huge difference between freezing and storing food in the refrigerator.

.jpg)

The difference between the two methods of freezing products

In fact, frozen products sold at supermarkets are all frozen (fast freezing), completely different from buying fresh and putting them in the freezer (slow freezing). Nam Ha Noi cold storage will explain this information more clearly in the next part of the article.

Refrigerator cannot be considered a freezing device even though it cools food because it cannot regulate the temperature and humidity accurately as well as perform rapid cooling like standard food freezers.

Through the above answers, businesses can also realize that the use of food freezing equipment is necessary when trading frozen goods. So let's find out how it affects food as well as the types of freezers currently on the market in the following section.

Food freezing equipment – A good solution to preserve product quality before storage

Businesses may not know that improperly frozen products will seriously affect the quality, taste, and color. That is also the reason why many people who use frozen food feel pale and unappetizing, even though the business has imported very fresh goods. Therefore, in order to have good and high-quality finished products, businesses need to use product freezing equipment because:

The main cause affecting the quality of frozen products is the crystallization process of water in food cells. Scientifically speaking: When not freezing properly (putting food in the freezer or in cold storage), the water crystals that are frozen in the large and dense cells outside the cell membrane will be inserted into the cell. The structure of muscle tissue is deformed results in the loss of food quality. Businesses can read more at THIS article to better understand.

The quality of frozen products may also be affected by the impacts of other physical - chemical - biological reactions such as oxidation, enzymatic reactions, the growth of molds, pathogenic microorganisms, etc. However, these impacts can also be slowed or stopped when the product is frozen.

In order to properly refrigerate the product, we need to use specially designed food freezers that can change the temperature of the food quickly. Nam Ha Noi cold storage would like to introduce to you the following types of food freezing equipment for reference.

The current food freezing equipment on the market

There are many ways to classify food freezing equipment, specifically as follows:

According to the using method, food freezing equipment are divided into 2 types:

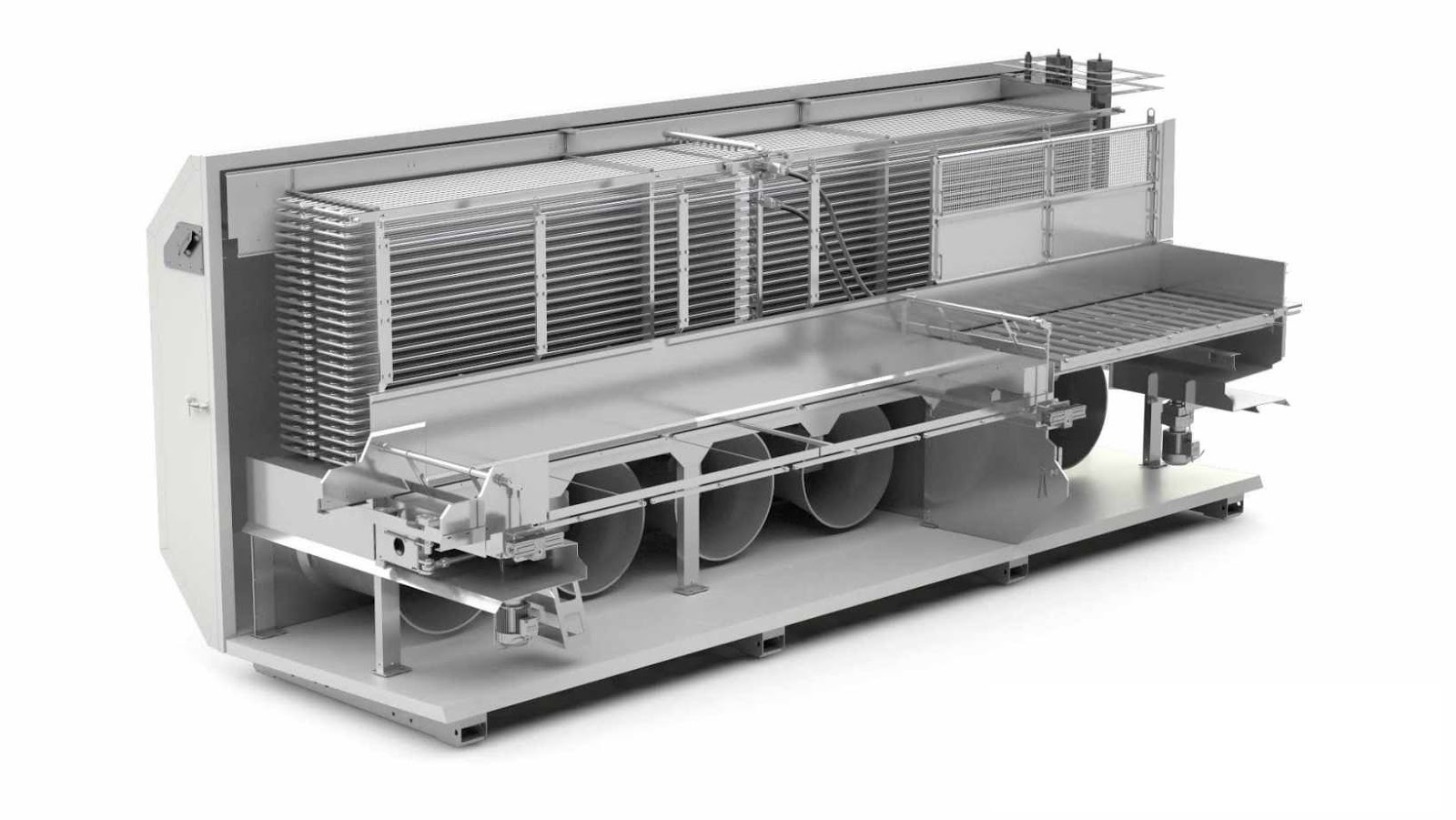

Type 1 - Integrated in the product processing line (IQF): IQF freezing system is the super speed freezing system for lively stocks. Conveyors use continuous freezing for products in the aquatic products and food processing industry. Freezing capacity are various, 250kg/h; 350kg/h; 500kg/h and depending on customer's request.

The IQF freezing system

Type 2: Applicable to block products mentioned below.

According to the method of heat transfer, food freezing equipment are divided into 3 types:

Air Blast Freezer - Using air to transfer heat:

Air Blast freezer is equipped in cold storage

Carry out freezing products using forced cold wind. The cooler will create a low-temperature air stream, then the air will be pushed by the blower system to freeze the product.

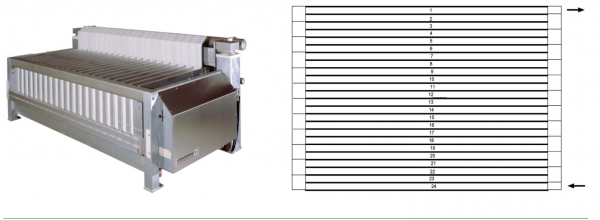

Contact Freezer - Freezing through instillment:

Contact Freezer

Products to be refrigerated are placed on trays and sandwiched between freezer shakers. The metal shaking plates are hollow inside to let the refrigerant flow through, the evaporation temperature reaches from –40oC to -45oC. Thanks to the direct instillment, the cold heat exchange is relatively efficient and the freezing time is significantly shortened compared to the wind freezer. Contact freezing method is usually applied to block products.

Freezers - Using liquefied gas to freeze products

Freezers use liquefied nitrogen

These freezers use liquefiable gas, nitrogen, or carbon dioxide to create chilled vapor and then freeze the product.

All of the above methods are used in the food processing industry. However, the most commonly used food freezers are still line-operated systems that integrate with processing and packaging operations.

Nam Ha Noi cold storage – The company with the most advanced food freezing equipment!

Nam Ha Noi cold storage believes that the following sharing will help businesses better understand the product freezing as well as equipment to serve this problem.

If your business is looking for a company that has both food freezing equipment and frozen storage, do not hesitate to contact Nam Ha Noi cold storage immediately. We are one of the best companies with storage and refrigeration services in Hanoi.

With 20 years of experience in the frozen industry, we understand what food retailers and businesses really need and always strive to meet that. Not only is a cold storage service to preserve goods, we can also give you much more, typically the FAST FREEZING PRODUCTS service right at our warehouse.

Nam Ha Noi cold storage is ready to serve any small to large needs of your business in the most professional and prestigious way! Please contact us via HOTLINE 0772.84.9999 for advice as soon as possible!

Visit Nam Ha Noi cold storage today to experience the best cold storage service!